How It Works

MADE IN THE USA INDUSTRIAL COVERS

Built For Precision. Backed By Process.

At Equip, we don’t guess. We engineer. Whether you’re starting with detailed CAD files or a quick sketch, we guide you through a clear, collaborative process to create the exact cover you need.

From design to delivery, everything happens under one roof at our Colorado Springs facility. No overseas outsourcing. No delays. Just expertly made, American-built soft goods that do their job and do it well.

OUR PROCESS

Every Project Follows the Same Proven Steps:

WHAT WE CAN MAKE

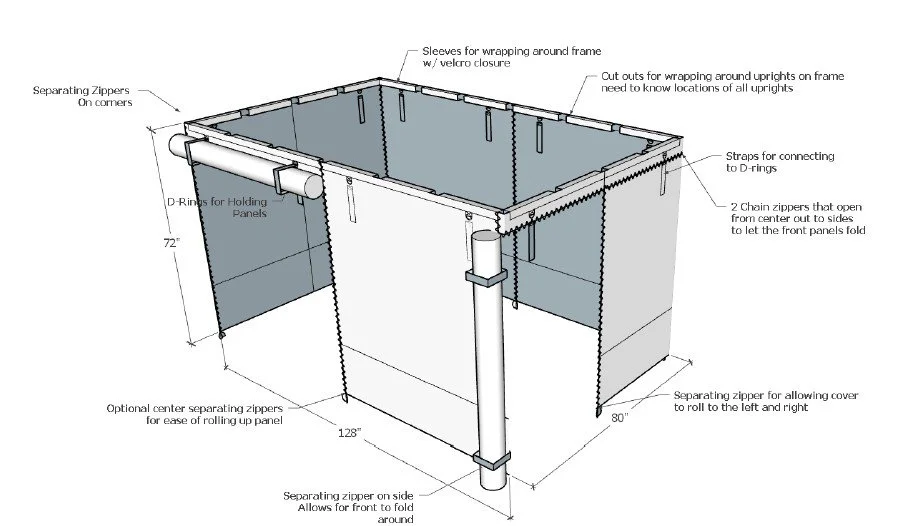

Custom Shapes. Unique Sizes. Specialized Equipment.

If you need something that doesn’t exist off-the-shelf, we can help. We specialize in custom solutions and create covers for all kinds of equipment across industries. If it needs to be protected, we can design a way to cover it.

We’ve Made Covers For:

Department of Defense and Aerospace

Medical and high tech equipment

RMUs & Retail Kiosks

Airport Check In Counters & Ticket Kiosks

Security Curtains & Intrusion Barriers

Stadium & Concession Equipment

Amusement Park Concession Stands & Crowd Control Barriers

Not sure if we can make it? Try us. We love a challenge.

WORKING WITH EQUIP

Built on Process. Powered by People.

When you work with Equip Your Space, you’re not just ordering a product, you’re partnering with a responsive, experienced team that’s here to get it right. From the first quote to final delivery we keep things clear, efficient, and personal.

The Equip Advantage:

No Minimum Order Quantities — We welcome one-offs and small runs

Clear Communication — You’ll talk to real people who know your project

Fast Turnarounds — We don’t outsource or overpromise

Repeat-Friendly — Need to reorder later? We’ve got your specs on file

What Our Customers Say About Us

Ready To Get Started?

Whether you're covering a kiosk or protecting mission-critical tech, we’re ready to help. Send us your specs, and we’ll take it from there.